IT-Works 3d Refurbished Printers and Toolheads available

We have 2 1.04 Mini’s in stock with LCD Screen installed ready to go right now for $995.98. We also…

Featuring Lulzbot 3D Printers, Parts, Toolheads, Filament, and Supplies

We have 2 1.04 Mini’s in stock with LCD Screen installed ready to go right now for $995.98. We also…

The New Lulzbot TAZ Workhorse Released! https://itworks3d.com/product/lulzbot-taz-workhorse-edition-printer-pre-order/ Get your TAZ Workhorse here at IT-Works 3d! Lulzbot TAZ Workhorse Edition 3d…

How to disassemble or tear down your E3D Titan Aero for maintenance, cleaning, removing a clog, replacing bearings, replacing the…

IT-Works 3D printed this Twisted 6 sided vase with our E3D Titan Aero 1.75mm toolhead for LulzBot Taz in 4 colors of…

MAKE STRONG PRINTS FAST WITH YOUR LulzBot® Taz 3D PRINTER! The newly released www.itworks3d.com E3D Titan Aero Volcano toolhead for…

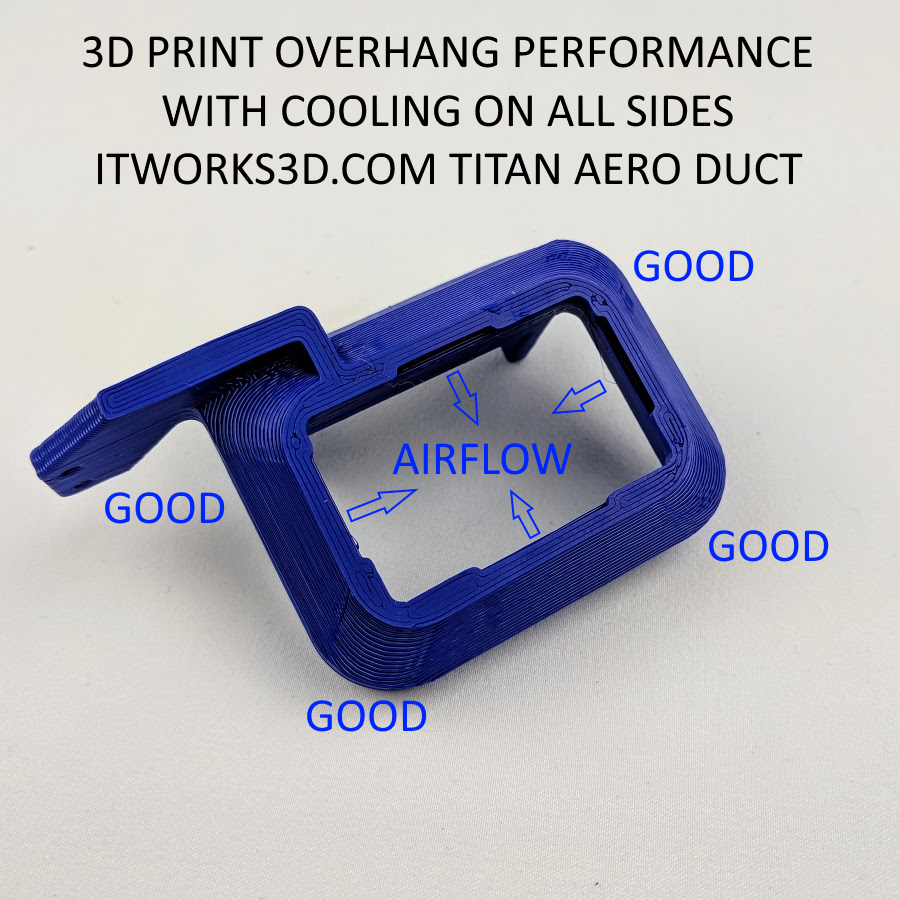

While printing filament cooling ducts for our E3D Titan Aero toolheads, I noticed that some ducts had consistently poorer print…