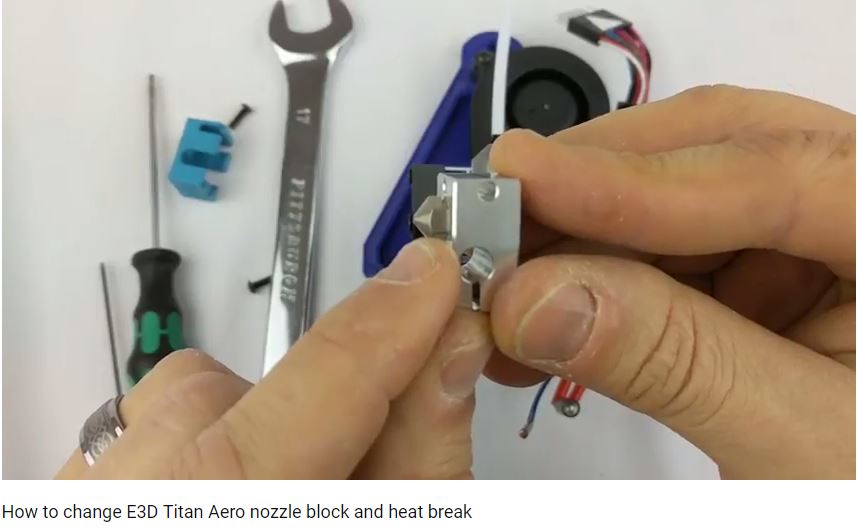

How to change Nozzle Heat block and Heat Break on E3D Titan Aero

Changing the nozzle, heater block, and heat break on the E3D Titan Aero V6 and Volcano hotend is easy. Our…

Changing the nozzle, heater block, and heat break on the E3D Titan Aero V6 and Volcano hotend is easy. Our…

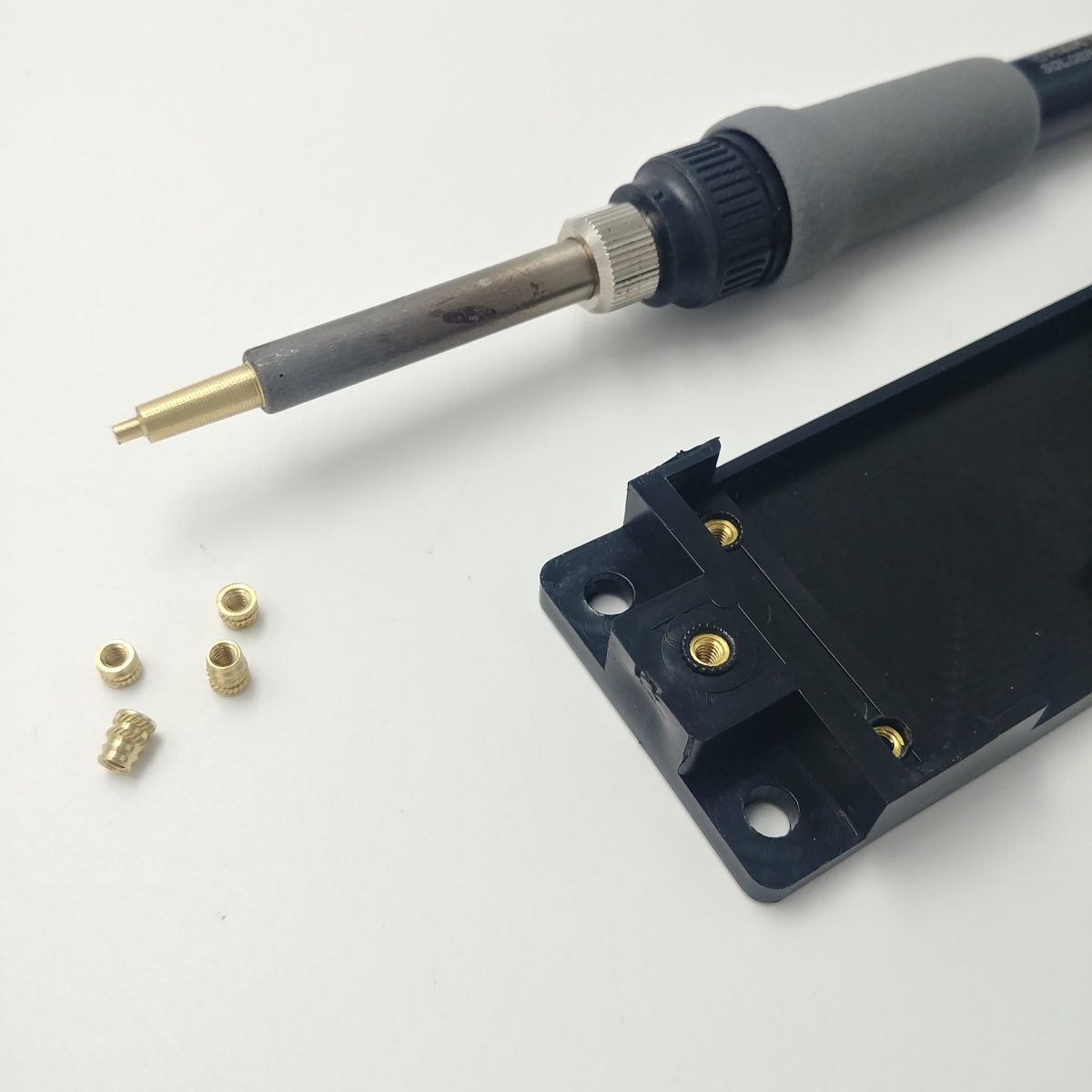

Threaded heat inserts are a great way to securely screw plastic parts together, but they can be a challenge to…

How to disassemble or tear down your E3D Titan Aero for maintenance, cleaning, removing a clog, replacing bearings, replacing the…

Learn how to remove connector pins that have bendable retaining tabs, re-bend the retaining tab without breaking it, and reinstall…

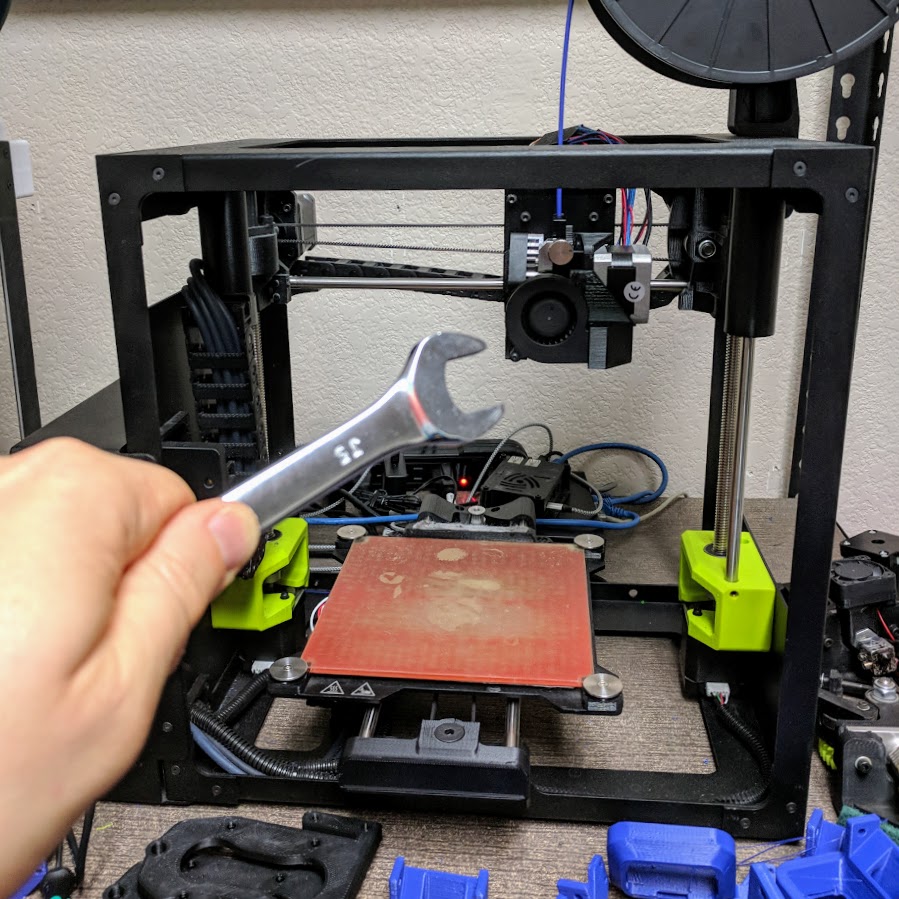

To keep your LulzBot Mini and Taz performing at their best, it’s important to check for wear and loose parts…

How do you set ESTEPs on the LulzBot TAZ? This video from our guides for the E3D Titan Aero Toolhead…