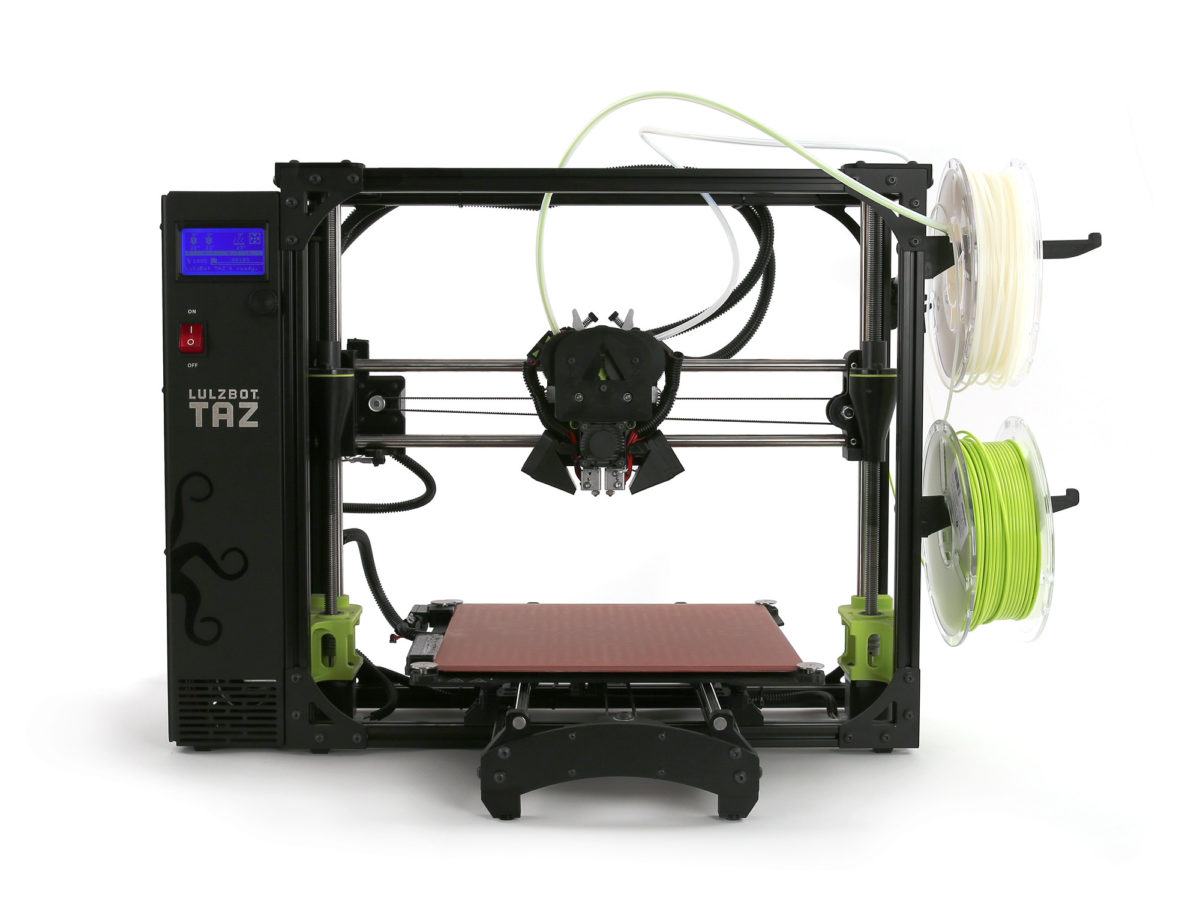

IT-Works 3d Refurbished TAZ 6 For Sale

IT-Works 3d has another refurbished TAZ 6 available for immediate sale!! This TAZ 6 has been cleaned, tested, has any…

Featuring Lulzbot 3D Printers, Parts, Toolheads, Filament, and Supplies

IT-Works 3d has another refurbished TAZ 6 available for immediate sale!! This TAZ 6 has been cleaned, tested, has any…

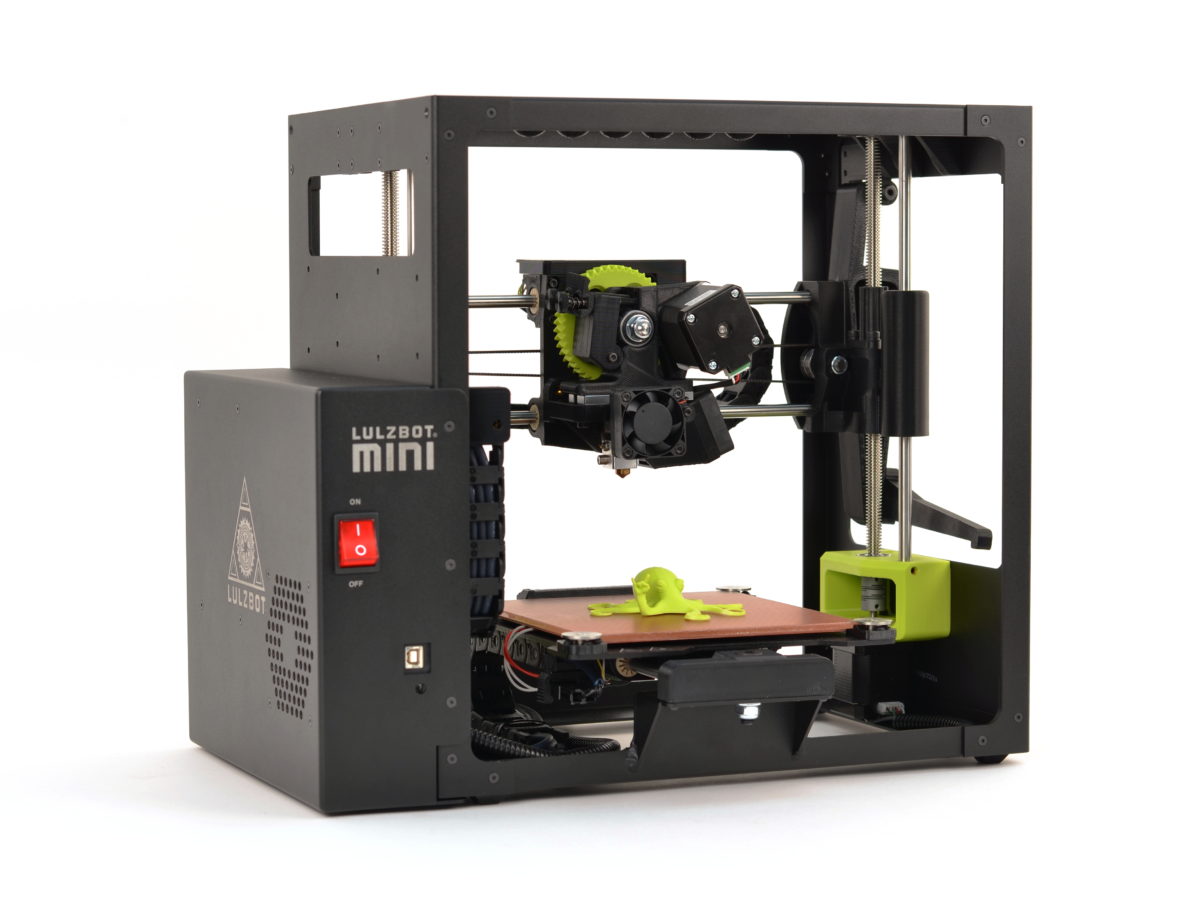

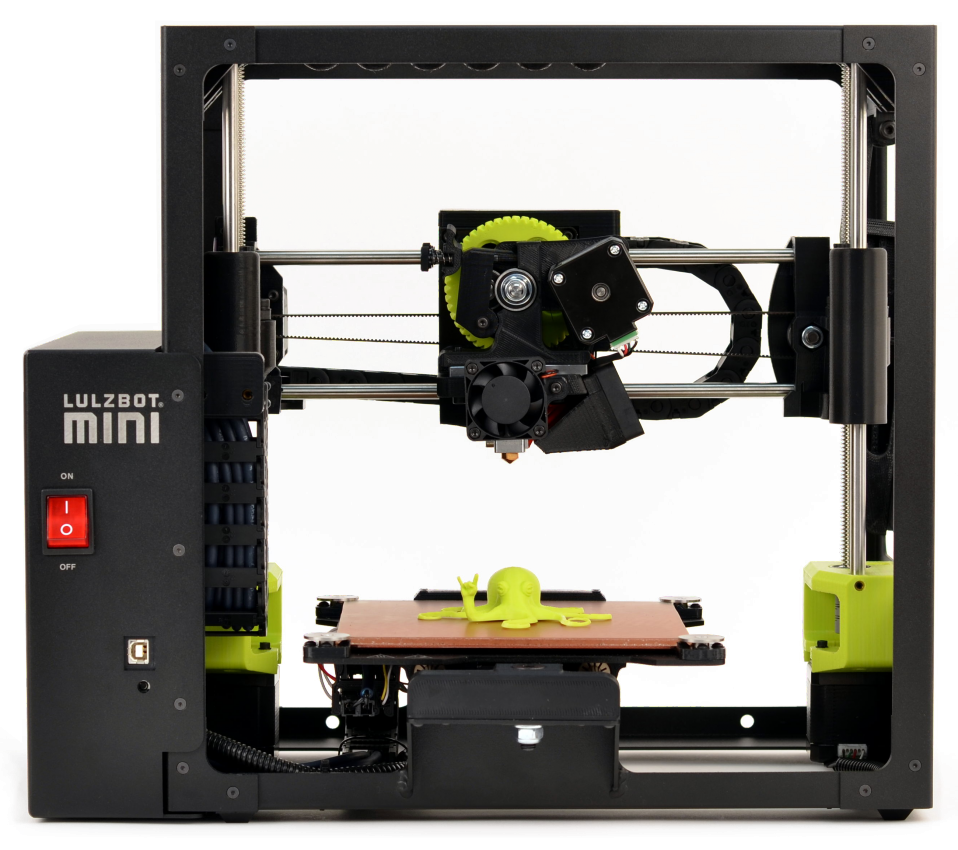

We have 2 1.04 Mini’s in stock with LCD Screen installed ready to go right now for $995.98. We also…

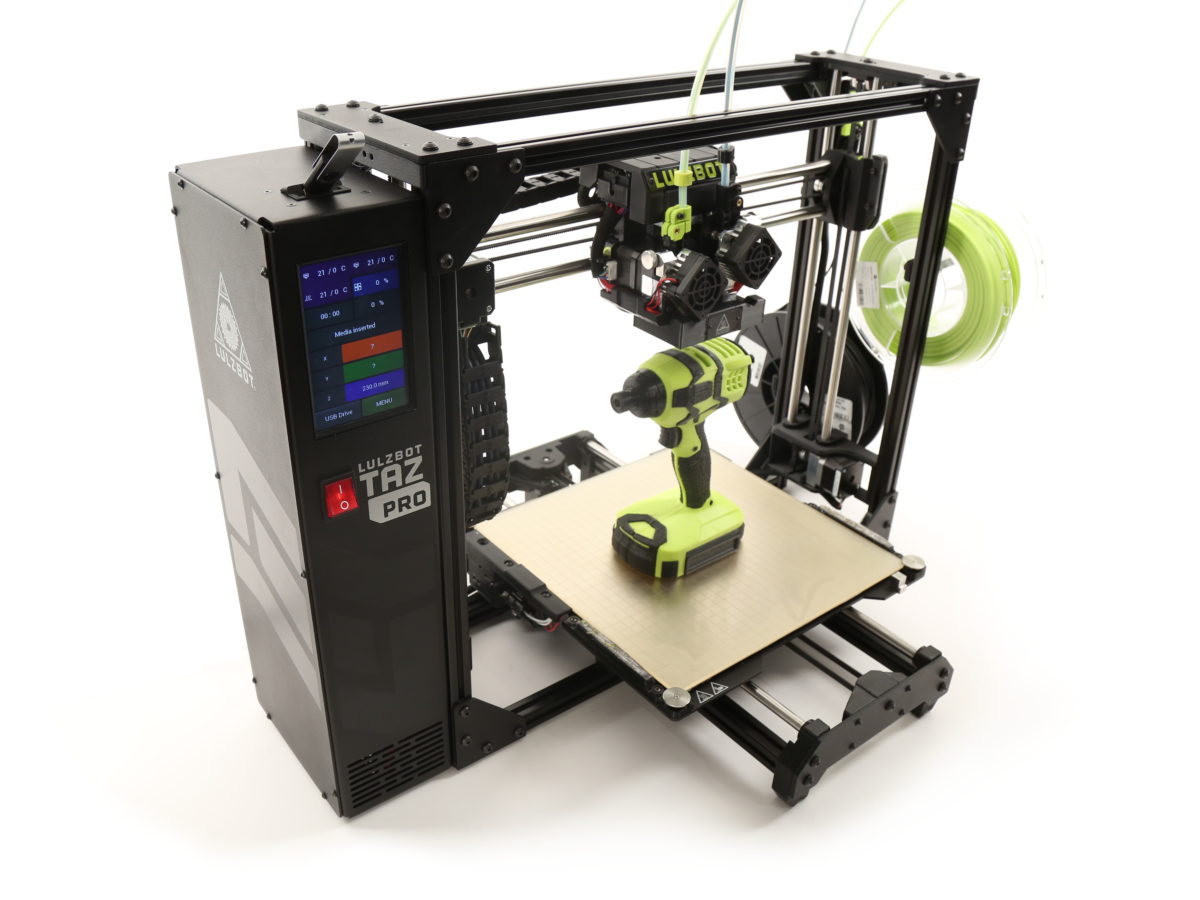

Tomorrow we will be releasing the Titan Aero PRO “X” Toolheads for Lulzbot 3d Printers. These will include a Nozzle…

We have 2 1.04 Mini’s in stock with LCD Screen installed ready to go right now for $995.98. We also…

SO MUCH in a single photo. @lulzbot3D @Creality3dprint @TheSeanConnelly @ITWorks3DPrint @deadmau5 pic.twitter.com/aepNeSkCHJ — Joel Telling – 3D Printing Nerd (@joeltelling)…

The newest addition to the award-winning LulzBot TAZ product line is here! The LulzBot TAZ Pro is an industrial grade…