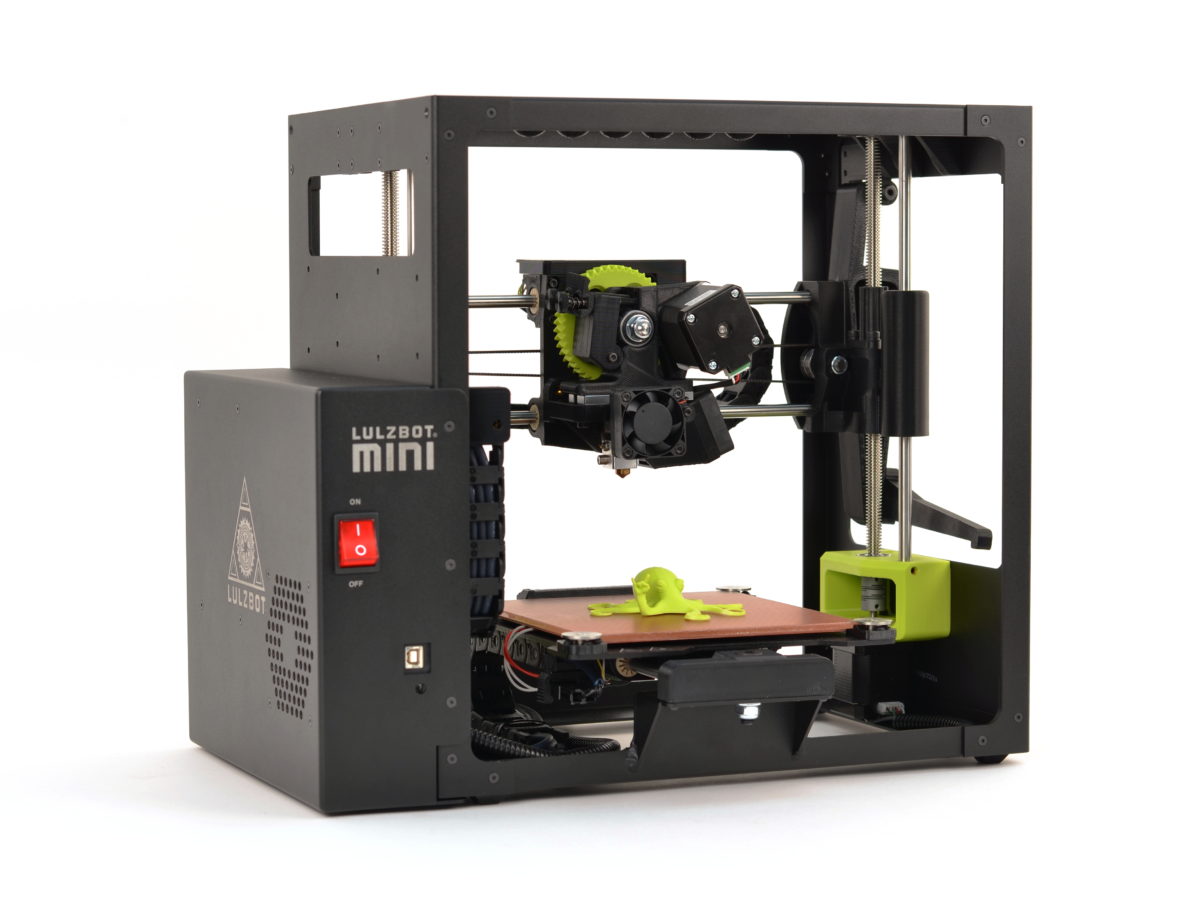

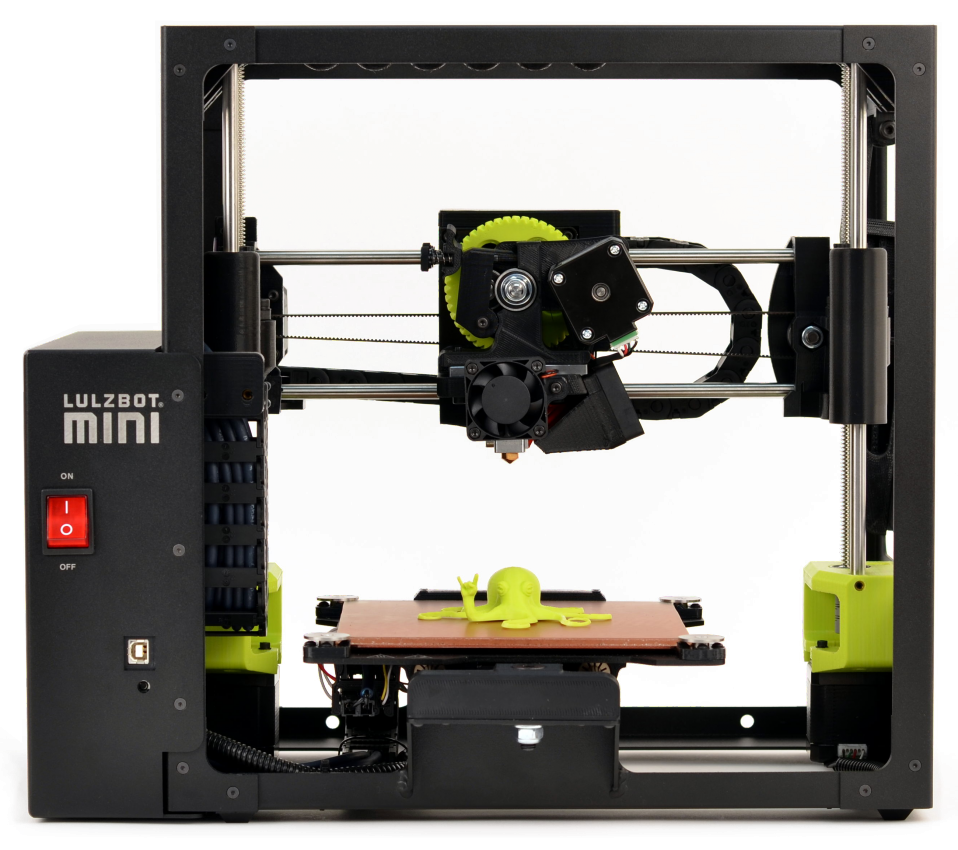

IT-Works 3d Refurbished Printers and Toolheads available

We have 2 1.04 Mini’s in stock with LCD Screen installed ready to go right now for $995.98. We also…

Featuring Lulzbot 3D Printers, Parts, Toolheads, Filament, and Supplies

We have 2 1.04 Mini’s in stock with LCD Screen installed ready to go right now for $995.98. We also…

We have 2 1.04 Mini’s in stock with LCD Screen installed ready to go right now for $995.98. We also…

We have 2 1.04 Mini’s in stock with LCD Screen installed ready to go right now for $995.98. We also…

Print solid AND flexible filaments on your LulzBot® Mini 3D printer, without changing toolheads! Available in your choice of either…

www.itworks3d.com will be releasing the E3D Titan Aero toolheads for LulzBot Mini very soon! The E3D Titan Aero allows you…

How do you get a reptile snake skin appearance in a 3D print? We stumbled onto a cool method! I…