Description

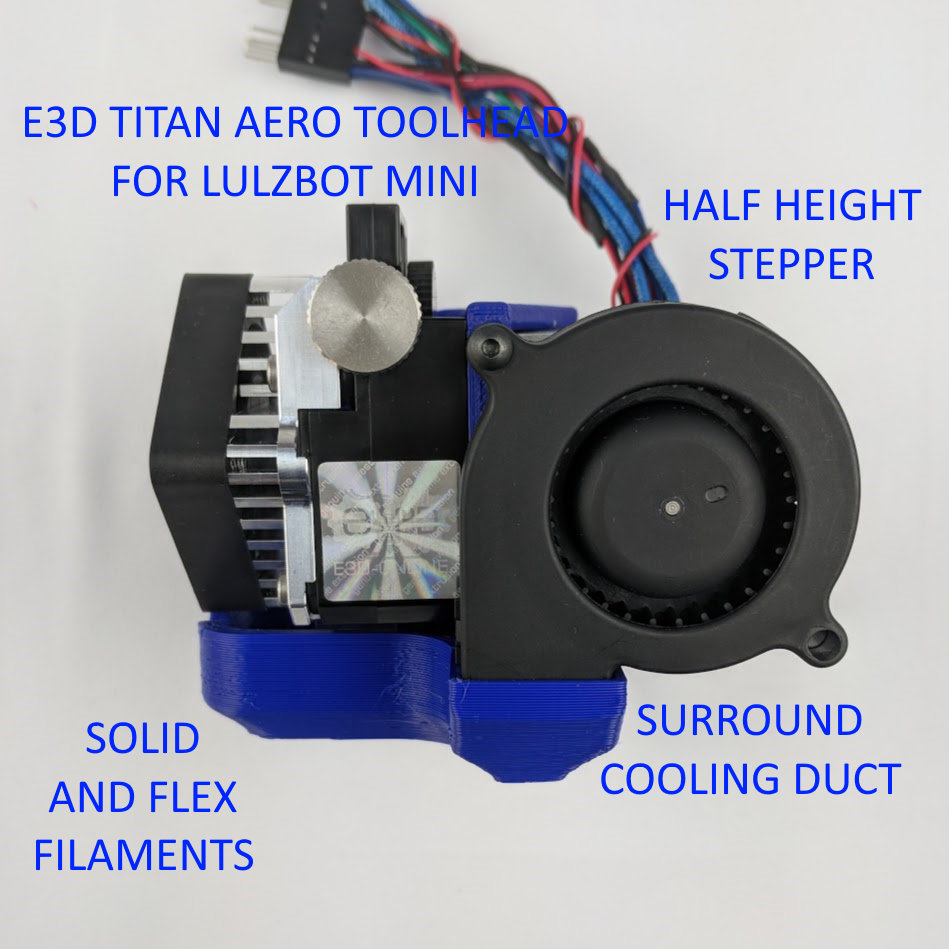

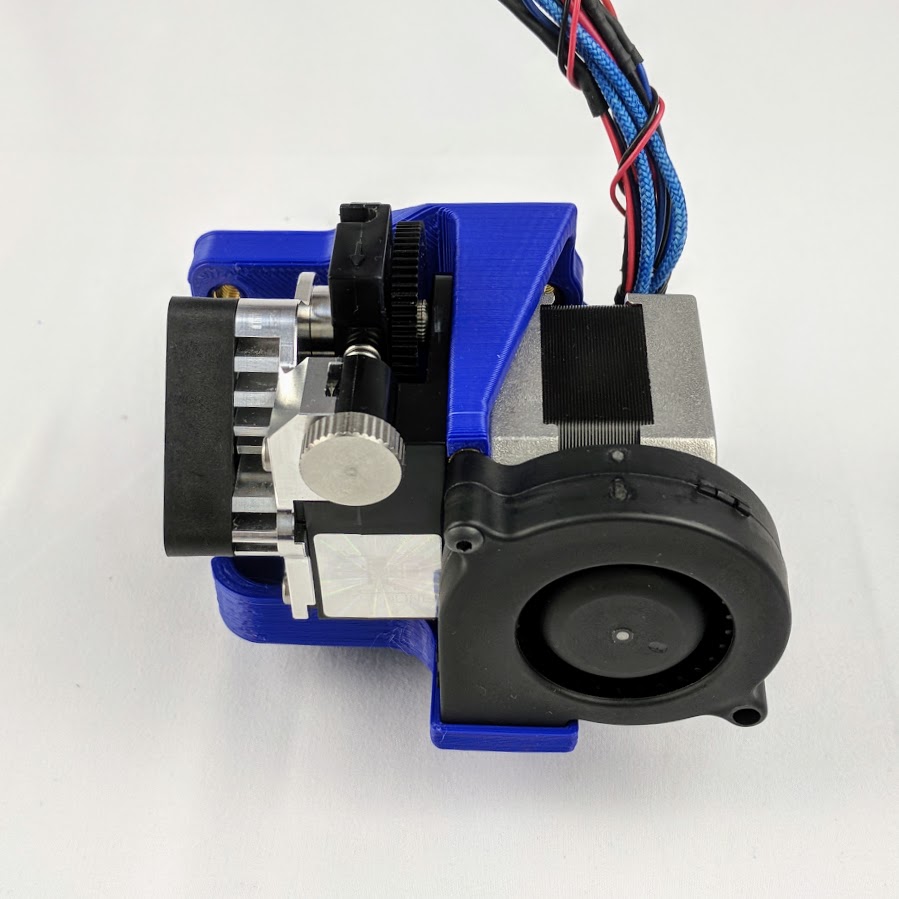

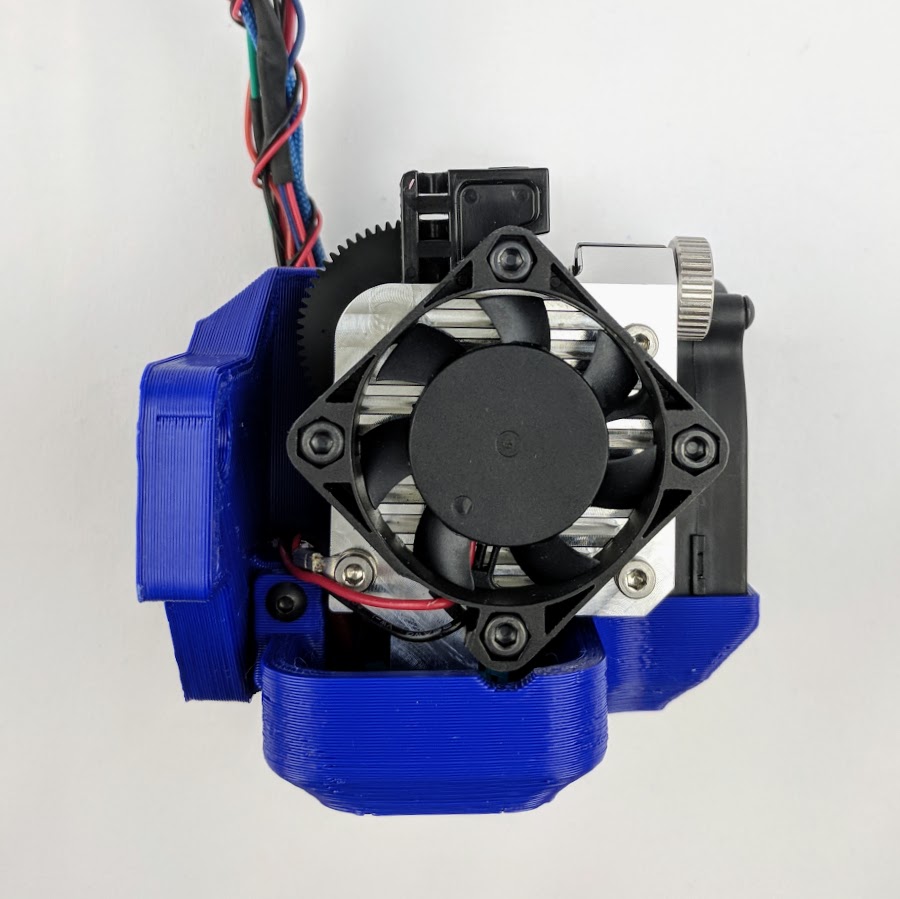

IT-Works developed this toolhead for the LulzBot® Mini around the E3D Titan Aero extruder and V6 hot end to give you these benefits:

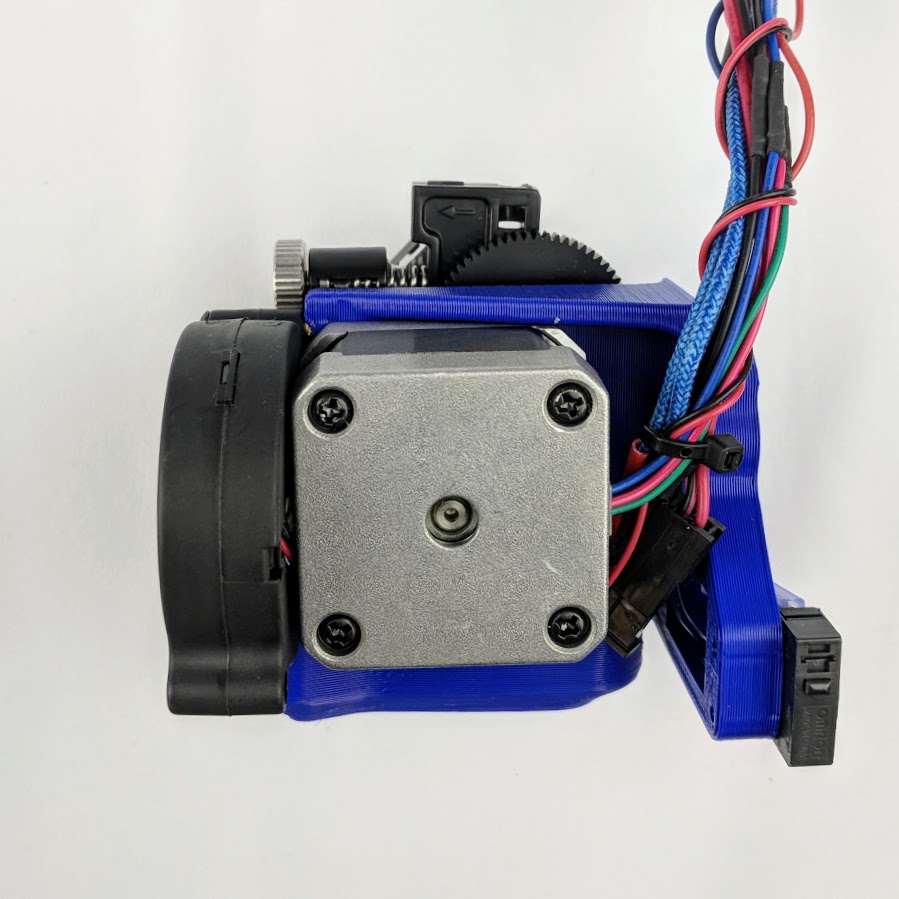

- Lighter weight stepper and components improve printhead placement accuracy and reduces wear

- Shorter filament path improves filament retraction and extrusion accuracy. By having a short, well constrained filament path, the Titan Aero is great for flexible filaments. It minimizes places where filament can bend, buckle and jam, giving a better flexible printing experience. The short filament path is also beneficial for regular filaments by improving extrusion responsiveness. This means that extrusion can start and stop more immediately, giving accurate, cleaner prints.

- Precision machined gears ensure accurate ESTEP calibration, and make for more consistent performance over time

- Surround cooling duct improves print performance. Here’s a real world example E3D Titan Aero duct improves print performance

- Ability to print solid and flexible filaments without changing toolheads

- Optional hardened parts reduce wear when printing abrasive filaments

- Titan Aero is built on the E3D V6 all metal design, allowing you to reliably print any thermoplastic at temperatures of more than 300°C.

- It’s also been designed to take standard V6 heatbreaks, so that you can interchange components from E3D’s entire modular ecosystem to suit your needs. Choose from temperature sensors, heater cartridges, Volcano, or one of the E3D’s 92 different nozzles.

- Available for 1.75mm filament, giving you a wider filament selection. Consider going this route. Cura 2 makes it easy to set up a machine and profiles for 1.75mm, and we will be testing a multi filament option that only works with 1.75mm.

The included nozzle size is .4mm, If you need a different size please add that and other upgrade options to the cart at the time of toolhead purchase.

Want upgrades for better durability with abrasive filaments (E3D Hardened hob, Micro Swiss wear resistant heat break, E3D Titanium Heat Break, nozzles, etc)? Add the upgrade items you want to the cart as well as a note during checkout, and we will install them for you.

Works with LulzBot® Mini Version 1.02 Foxglove and 1.03 Gladiola 1.04

60 day warranty and support from IT-Works

*** This is not a LulzBot® product and LulzBot® does not support or warranty this toolhead ***

Please Allow 1-2 days for build and shipping.

Q&A:

How to order with upgraded parts

For us to build the toolhead with upgraded parts, where we keep the original parts, On the order:

Parts you want installed

Toolhead.

In the order note, ask that the upgrade parts be installed

Please allow up to 2 business days for building and testing the custom toolhead

For us to build the toolhead with upgraded parts, you receive the original parts: On the order:

Parts you want installed

Toolhead.

$50 (qty 100) of https://itworks3d.com/product/labor-misc/

In the order note, ask that the upgrade parts be installed

Please allow up to 2 business days for building and testing the custom toolhead

A suggested order where we keep the original parts would be:

Toolhead: 1 Titan Aero toolhead https://itworks3d.com/product/e3d-titan-aero-toolhead-for-lulzbot-mini/

Heat Break: 1 E3D Titanium heat break https://itworks3d.com/A: We suggest starting with higher base ESTEPs first. You can use the feed rate knob to fine tune extrusion.

Q: If I have a 3mm Titan Aero, can I print 1.75mm filament?

A: You can, but with a few qualifications.

- Ideally (but not required) you swap the 3mm filament guide insert below the hobbed bolt for a

- Don't print 1.75mm flexible filaments in a 3mm Titan Aero. The heatbreak and hotend would still be 3mm, making room for flexible 1.75 to coil and bunch up

- You'll need to experiment with flow and retraction retraction settings.

Q: Can I print faster with the Titan Aero toolhead without losing quality?

A: Testing has shown very good results with 50-100% faster print speeds, especially with flexible filaments. Try it!

Q: Where are the files for the printed parts?

Coming soon

Q: How about versions for the LulzBot Taz and dual/multiple filaments?

A: Here's the E3D Titan Aero Toolhead for LulzBot Taz https://itworks3d.com/product/lulzbot-taz-e3d-titan-aero-toolhead/

We are exploring compatibility of the 1.75mm Titan Aero toolheads and the Palette+ 4 filament system. ign up for our newsletter and/or follow us on Facebook for updates!

Q: What parts do I need to build my own E3D Titan Aero toolhead for the LulzBot Mini?

1 E3D TITAN AERO EXTRUDER 24V Mirrored

1 .5mm E3D V6 nozzle (a .4mm nozzle is included with the Titan Aero Extruder, if that works for you)

1 2x10 dual row connector housing

15 CONN PIN 24-30AWG CRIMP TIN Type Molex 0016020108 Male. Buy extras though if you're new to crimping these. We've found a PAD-11 crimper to be a good choice to crimp them.

1 FAN BLOWER 51.3X15MM BALL BEARING 24V RADIAL

1 FAN 40X10MM 5V AXIAL

1 MICRO SWITCH

1 FULL HEIGHT NEMA 17 STEPPER MOTOR. You CAN use half height stepper motors (and potentially even pancake steppers), but we've found them to not have enough torque in some situations.

1 screw kit

2 CONN QC RCPT 22-26AWG 0.110 (24-26awg insulated spade lugs. We use TE Connectivity 7-520366-2

1 CONN RING CIRC 22-26AWG #4 CRIMP We use Panduit P22-4R-M

A: We suggest starting with higher base ESTEPs first. You can use the feed rate knob to fine tune extrusion.

A: You can, but with a few qualifications.

- Ideally (but not required) you swap the 3mm filament guide insert below the hobbed bolt for a

- Don't print 1.75mm flexible filaments in a 3mm Titan Aero. The heatbreak and hotend would still be 3mm, making room for flexible 1.75 to coil and bunch up

- You'll need to experiment with flow and retraction retraction settings.

A: Testing has shown very good results with 50-100% faster print speeds, especially with flexible filaments. Try it!

Coming soon

A: Here's the E3D Titan Aero Toolhead for LulzBot Taz https://itworks3d.com/product/lulzbot-taz-e3d-titan-aero-toolhead/

We are exploring compatibility of the 1.75mm Titan Aero toolheads and the Palette+ 4 filament system. ign up for our newsletter and/or follow us on Facebook for updates!

1 E3D TITAN AERO EXTRUDER 24V Mirrored

1 .5mm E3D V6 nozzle (a .4mm nozzle is included with the Titan Aero Extruder, if that works for you)

1 2x10 dual row connector housing

15 CONN PIN 24-30AWG CRIMP TIN Type Molex 0016020108 Male. Buy extras though if you're new to crimping these. We've found a PAD-11 crimper to be a good choice to crimp them.

1 FAN BLOWER 51.3X15MM BALL BEARING 24V RADIAL

1 FAN 40X10MM 5V AXIAL

1 MICRO SWITCH

1 FULL HEIGHT NEMA 17 STEPPER MOTOR. You CAN use half height stepper motors (and potentially even pancake steppers), but we've found them to not have enough torque in some situations.

1 screw kit

2 CONN QC RCPT 22-26AWG 0.110 (24-26awg insulated spade lugs. We use TE Connectivity 7-520366-2

1 CONN RING CIRC 22-26AWG #4 CRIMP We use Panduit P22-4R-M

Installing, Using, and Maintaining the LulzBot® Mini E3D Titan Aero toolhead:

Unloading filament

- Video: How to Unload filament with the E3D Titan Aero

- Heat the hotend to a suitable filament change temperature- 200C is good for ABS, PLA, PETG, TPU

- In Cura, retract approx 100mm of filament, until the loaded filament retracts clear of the hobbed feed bolt

- Pull up on the filament with moderate force while it's retracting to prevent soft filament from wadding up between the hob and the underside of the idler lever until the filament pulls free of the top of the idler lever.

- Be sure to not leave PLA sitting stationary in a heated hotend, or to heat it past recommended temperatures, as this can cause crystallization, possibly requiring replacement parts.

- We do not recommend manually inserting or removing filament, as improper removal can result in jamming.

Uninstalling a toolhead on the LulzBot Mini

- Unload filament from the installed toolhead

- Note the ESTEPS for the current toolhead if you don't know them- Step 9 in LulzBot's toolhead calibration guide. We suggest labeling the toolhead for future reference.

- Note the ESTEPs on the label on the E3D Titan Aero toolhead- either on the back or on the stepper motor.

- Turn off power to the printer

- Using a 2.5mm hex head wrench, remove the two screws that hold the X Carriage Cap in place. Lift the X carriage cap up to expose the toolhead connector

- Unplug the toolhead connector from the toolhead harness.

- Don't get burned! If the hotend was heated, wait for it to cool to a safe handling temperature.

- (for earlier 1.02 Gladiola Minis) carefully clip the cable ties that secure the harness to the X carriage

- While supporting the toolhead, use a 4mm hex head wrench to remove the 3 screws on the back of the x carriage that secure the toolhead mount to the X carriage.

- Lift the toolhead toward the front of the printer to remove it from the X carriage

Installing a toolhead on the LulzBot Mini

- Hold the toolhead with the back plate vertical

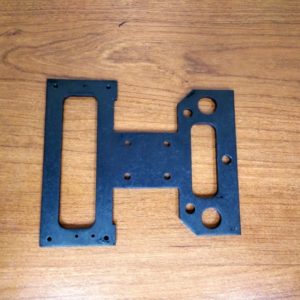

- Place the toolhead mounting plate against teh X carriage, lining up the rectangular alignment guide on the X carraige with the rectangular laignment hole on the toolheaf mounting plate, and press and hold in place.

- While supporting the toolhead, , use a 4mm hex wrench to insert the 3 mounting screws through holes in the X carriage and thread them into brass inserts in the toolhead mounting plate. Tighten the 3 screws until snug, and ensure that the toolhead mounting plate is flat against the X carriage.

- Plug the toolhead connector into the toolhead harness, taking care to insert the pins straight and into their correct mates. Pins should insert into holes with silver connectors to receive them. You can see if a hole is empty by looking at the side of the connector and checking the small holes that the pins and connectors locking clips snap into.

- Place the X Carriage Cap over the toolhead connector and wires, ensuring that the wires are not pinched or loose where they can rub of become entangled. Using a 2.5mm hex wrench, install the 2 screws in the top of the x carriage cap. TIP: If you have the earlier Foxglove Mini where the toolhead wires were secured by cable ties, print yourself a Gladiola X carriage cap, which has a handy channel to route the wires. No more cable ties!

- Turn the printer on and check that the heat sink cooling fan on the left is spinning. It should be spinning whenever the printer is turned on. If it is not spinning, turn the printer off and double check that the connector is plugged in correctly.

- If the heatsink cooling fan is spinning, either set up the toolhead in Cura, or select the correct machine for the filament you are using in Cura, then load filament

Install Cura 2

Cura 2 LuzlBot Edition now contains firmware and profiles optimized for the E3D Titan Aero, allowing you to easily switch between profile for solid and flexible filament, and well as easy configuration for 1.75mm filament and alternative nozzle sizes from the factory .5mm size. Thanks LulzBot!

- Download Cura 2 from https://www.lulzbot.com/cura

- At first run, you'll be asked to Add Machine, select: LulzBot Mini AeroStruder

- To add a machine after first run: Settings > Printer > Add Printer

- At the bottom of the window, give it a descriptive name, especially if you're using 1.75mm filament or other nozzle sizes.

- Click Add Printer

- Set the filament size and nozzle size you purchased (defaults are 2.85mm and 0.5mm)

- Click Finish

- Click Close

Flash Firmware

- From Cura 2 LulzBot Edition, available at lulzbot.com/cura

- Select the correct printer from the pulldown in the upper right

- Settings > Printer > Manage Printers

- Check that the correct printer is highlighted under the Printers list

- Turn the printer on

- Connect the printer to the computer with a USB cable

- Click Upgrade Firmware

- Click Upgrade Firmware Automatically

- Wait for the firmware to flash, click OK and close as needed when it's done.

- Be sure to update ESTEPS. THe factory ESTEPS included with the firmware are 420. Make sure this is correct for your machine, filament and toolhead by performing and ESTEPS calibration

Update ESTEPs and ESTEP Calibration

For proper operation, the ESTEPS for every toolhead need to be and stored in the printer.

Change and save ESTEPS of 415 using the instructions in this handy video Video: How to store ETEPS in a LulzBot TAZ 3D printer (the Cura steps apply to the Mini as well)

(Optional) Calibrate ESTEPS:

For best operation, it's a good idea to calibrate the ESTEPS to minimize under or over-extrusion

To calibrate ESTEPS:

- Open Cura

- Load a model (it doesn’t matter what)

- Open the Control window

- Heat up the nozzle to the proper printing temperature for your filament

- Load your filament using the extrude 10mm button- around 50mm should do it.

- Mark the filament at 100mm and 120mm above the idler

- In the lower right of the control window, there is a white text box where you type in the appropriate Gx Fxx Exxx (USE CAPITAL LETTERS) below, then press enter

- G92 E0

- For Flexible filament: G1 F30 E100

- For Solid filament: G1 F50 E100

Fxx is the feed rate in mm, Exx is the length of filament to extrude. It’s also good idea to calibrate your other toolheads, if you’ve not done so.

- The toolhead will extrude, then stop.

- Make note of how high or low above the toolhead the 100mm mark fell. If it over-extrudes past the 100mm mark, you can measure to the 120mm mark to gauge how much it over-extruded

- Adjust the ESTEPS, increase or decrease them approx. 6 steps per 1 mm of under or over-extrusion, then save them to the printer:

- M92 Exxx

(this sets the new ESTEPS. E400, E432, E411, etc) - M500

(this saves the ESTEPS to the printer) - M501

(this displays the settings, check that your new ESTEPS are saved)

- Close the control window

- Repeat from step 3 until the 100mm mark reaches the point you measured from (the toolhead is extruding 100mm)

Repeat this process for flexible filament you use. We have found that ESTEPs may vary depending on the flexibility of the filament used, so it’s a good idea to calibrate ESTEPs for your filament.

Tune Thermistor PID factors (only needed if you haven't updated with Cura 2 Firmware)

Here's a good summary of the process found at lincomatic.com to fine tune your thermistor PID settings in your printer's Marlin firmware to better maintain hot end temperature:

- Allow your hot end to cool to room temp.

- In the terminal in Cura, send the following command: M303 S230 if extruding filament at 230. Change the number in the command to reflect the temperature at which you normally extrude. The M303 SXXX command will tune the extruder.

The hot end will then heat up and finally cool, while logging the temperature. When completed, similar values will be displayed:

bias: 101 d: 101 min: 145.48 max: 154.02

Ku: 64.06 Tu: 29.67

Clasic PID

Kp: 19.5

Ki: 1.5

Kd: 63.48

Type that information into the Cura terminal box using the following format, with your values substituted appropriately, then press enter:

M301 P19.50 I1.50 D63.48

Enter the following command and press enter to save the PID settings to EEPROM.

M500

Add “machines” with ESTEPs for flexible filament in Cura

We've found that correct ESTEPs for the E3D Titan Aero vary depending on the stiffness of the filament. Softer filaments need around 25% higher ESTEPs, and medium flex filaments need around 10% higher.

Here's how to set ESTEPs for different filaments in Cura LulzBot Edition. We know it's a bit of work, but it will make swapping between flex and solid filaments quick and easy!

- Note the ESTEPs on the label on the toolhead- either on the back or on the stepper motor. If you don't have the label handy, start with 400 ESTEPs for solid filaments

- Open Cura LulzBot Edition (direction Below based on Cura LulzBot Edition Version 21.0X)

- "Machine" menu

- "Add New Machine..."

- LulzBot Mini

- LulzBot Mini with Flexystruder

- Finish

- "Machine" menu

- Ensure the Machine you just added is selected

- Machine Settings

- Change Machine Name

- Enter a new name that will be useful like LulzBot Mini Aero Flexibles, Click OK

- In the "E-Steps per 1mm of filament", enter appropriate ESTEPs for the filament you are printing. Around 400 for solid, 440 for semi flexible, 500 for soft filaments. Click OK

- Follow the steps in "calibrating Your Toolhead" to get the correct ESTEPs for your filament and toolhead on your printer

- Repeat from Step 3 for each of the filaments you intend to use. We recommend at least 1 "Machine" for each of solid and flexible filament.

Switching Between Filament Types with the E3D Titan Aero toolhead installed (Flexible filament profiles: change nozzle from .6mm to .5mm)

- Machine Menu

- Select the "Machine" you that you intend to use that you created earlier (LulzBot Mini Aero Flexibles)

- Select the filament and quality you want to print

- If printing flexibles, check that a .5mm nozzle is set in the profile

- Expert Menu

- Switch to Full Settings

- Yes to "Copy the settings from quickprint...."

- Advanced tab

- Check that Nozzle size (mm) is .5mm

- We DO offer additional optional E3D nozzles in different sizes!

- You can Save the profile settings to preserve the nozzle size and any other tuning you've done

- File menu> Save Profile, Save the .ini file somewhere convenient.

- File menu> Open Profile to load the .ini file you created later

Loading Filament

- Video: How to load filament with the E3D Titan Aero

- Heat the hotend to a suitable filament change temperature- 200C is good for ABS, PLA, PETG, TPU

- Trim the end of the filament square

- Ensure the tension knob is set properly- approx 2 turns from fully loose for solid filaments. Some flexibles need another 1-2 turns tighter.

- Push the filament in through the hole in the filament lever until it is pressing with moderate pressure against the hobbed bolt below the filament lever

- In Cura, extrude approx 100mm of filament until the new filament pushes the prior filament out through the nozzle. This is known as "purging" the old filament.

- Push the filament down into the idler until the hob has grabbed the filament and is feeding the filament.

- Be sure to not leave PLA sitting stationary in a heated hotend, or to heat it past recommended temperatures, as this can cause crystallization, possibly requiring replacement parts.

- We do not recommend manually inserting or removing filament, as improper removal can result in jamming

Setting the E3D Titan Aero Filament Tension knob

- We have found that a good starting tension knob adjustment is 1.5 turns for hard filament and 2-3 turns for softer filaments.

- Per the E3D Titan Aero Wiki's "Adjusting Idler Force" section: "The idler force can be adjusted using the thumb wheel on the side of the extruder. The nut and spring that actually apply the force can be viewed through the lid, giving a quick indicator of the force being applied. The force required will depend on a range of parameters, such as filament material, filament diameter, extrusion rate etc. As a general rule softer filaments (such as flexibles) will need less force than harder ones as the hobb can more easily grip them. The idler force does not need to be perfect in order to print, however to get the best settings for your printer and material combination we advise a little bit of experimentation to find a setting that feels right."

1.75 Filament Profile Adjustments for Cura

- Change the filament diameter in your Cura profiles to 1.75

- Reduce retraction distance by half or more to avoid retracting the filament up into the heat break or filament guide. Do this in the Start .Gcode section- change the line G1 E-30 F100 to G1 E-15 F100

- Save the filament profile for later use

How to change nozzle on the E3D Titan Aero hotend

To swap out a nozzle, you must follow this procedure - being careful not to burn yourself.

Here's a video on How To Remove and E3D Nozzle

- Unscrew the heat-break from the HeatSink half a turn to be sure you are not tightening against the heat-break in later stages.

- Heat up your HotEnd to 285°C. Do not overshoot as you risk damaging your thermistor.

- Remove the existing nozzle from the heater block.

- Insert the new nozzle.

- Gripping the heater block tighten the nozzle. Do not apply any torque through the heat-break, they are fragile.

- Turn off the heat and allow the HotSide to cool.

- Re-tighten the heat-break into the HeatSink.

Removing Stuck Filament

Heat the hotend to printing temperature for the loaded filament

Loosen the idler tension knob all the way by turning clockwise until it stops

Pull the idler toward you so it's no longer pressing the filament against the hob gear

Try pushing the filament through manually.

If you can get push the filament through through, check the hob for plastic debris and clean as necessary (be sure to rotate it to see all the ridges)

Tighten the idler tension bolt again around 1.5 turn CCW

From the LCD or Cura, extrude around 40mm of filament to purge the filament

To remove the filamant after purging: From the LCD or Cura, retract around 40mm of filament, pulling up on the filament with moderate force to ensure the filament is fully removed from the idler which prevents blobs of filament hardeneing between the idler bottom and hob gear, preventing removal in the future.

If these steps fail, there may be a filament frangment stuck in the filament path. Try disassembling the toolhead to clear the filament path.

Here's a video on How To Disassemble the IT-Works Titan Aero Toolhead

How to adjust Z offset if the nozzle is too high or low

If the nozzle is consitantly too high or too low, and the nozzle isn't pushing down the corner washers during leveling, leading to flase level settings, follow these steps to adjust the Z offset:

- Open Cura

- Load a file to print (it doesn't matter which)

- Open the control /console window

- Display the firmware settings by: M501 nter>

- Check that the Z offset saved: M501

- Video: How to Unload filament with the E3D Titan Aero

- Heat the hotend to a suitable filament change temperature- 200C is good for ABS, PLA, PETG, TPU

- In Cura, retract approx 100mm of filament, until the loaded filament retracts clear of the hobbed feed bolt

- Pull up on the filament with moderate force while it's retracting to prevent soft filament from wadding up between the hob and the underside of the idler lever until the filament pulls free of the top of the idler lever.

- Be sure to not leave PLA sitting stationary in a heated hotend, or to heat it past recommended temperatures, as this can cause crystallization, possibly requiring replacement parts.

- We do not recommend manually inserting or removing filament, as improper removal can result in jamming.

- Unload filament from the installed toolhead

- Note the ESTEPS for the current toolhead if you don't know them- Step 9 in LulzBot's toolhead calibration guide. We suggest labeling the toolhead for future reference.

- Note the ESTEPs on the label on the E3D Titan Aero toolhead- either on the back or on the stepper motor.

- Turn off power to the printer

- Using a 2.5mm hex head wrench, remove the two screws that hold the X Carriage Cap in place. Lift the X carriage cap up to expose the toolhead connector

- Unplug the toolhead connector from the toolhead harness.

- Don't get burned! If the hotend was heated, wait for it to cool to a safe handling temperature.

- (for earlier 1.02 Gladiola Minis) carefully clip the cable ties that secure the harness to the X carriage

- While supporting the toolhead, use a 4mm hex head wrench to remove the 3 screws on the back of the x carriage that secure the toolhead mount to the X carriage.

- Lift the toolhead toward the front of the printer to remove it from the X carriage

- Hold the toolhead with the back plate vertical

- Place the toolhead mounting plate against teh X carriage, lining up the rectangular alignment guide on the X carraige with the rectangular laignment hole on the toolheaf mounting plate, and press and hold in place.

- While supporting the toolhead, , use a 4mm hex wrench to insert the 3 mounting screws through holes in the X carriage and thread them into brass inserts in the toolhead mounting plate. Tighten the 3 screws until snug, and ensure that the toolhead mounting plate is flat against the X carriage.

- Plug the toolhead connector into the toolhead harness, taking care to insert the pins straight and into their correct mates. Pins should insert into holes with silver connectors to receive them. You can see if a hole is empty by looking at the side of the connector and checking the small holes that the pins and connectors locking clips snap into.

- Place the X Carriage Cap over the toolhead connector and wires, ensuring that the wires are not pinched or loose where they can rub of become entangled. Using a 2.5mm hex wrench, install the 2 screws in the top of the x carriage cap. TIP: If you have the earlier Foxglove Mini where the toolhead wires were secured by cable ties, print yourself a Gladiola X carriage cap, which has a handy channel to route the wires. No more cable ties!

- Turn the printer on and check that the heat sink cooling fan on the left is spinning. It should be spinning whenever the printer is turned on. If it is not spinning, turn the printer off and double check that the connector is plugged in correctly.

- If the heatsink cooling fan is spinning, either set up the toolhead in Cura, or select the correct machine for the filament you are using in Cura, then load filament

Cura 2 LuzlBot Edition now contains firmware and profiles optimized for the E3D Titan Aero, allowing you to easily switch between profile for solid and flexible filament, and well as easy configuration for 1.75mm filament and alternative nozzle sizes from the factory .5mm size. Thanks LulzBot!

- Download Cura 2 from https://www.lulzbot.com/cura

- At first run, you'll be asked to Add Machine, select: LulzBot Mini AeroStruder

- To add a machine after first run: Settings > Printer > Add Printer

- At the bottom of the window, give it a descriptive name, especially if you're using 1.75mm filament or other nozzle sizes.

- Click Add Printer

- Set the filament size and nozzle size you purchased (defaults are 2.85mm and 0.5mm)

- Click Finish

- Click Close

- From Cura 2 LulzBot Edition, available at lulzbot.com/cura

- Select the correct printer from the pulldown in the upper right

- Settings > Printer > Manage Printers

- Check that the correct printer is highlighted under the Printers list

- Turn the printer on

- Connect the printer to the computer with a USB cable

- Click Upgrade Firmware

- Click Upgrade Firmware Automatically

- Wait for the firmware to flash, click OK and close as needed when it's done.

- Be sure to update ESTEPS. THe factory ESTEPS included with the firmware are 420. Make sure this is correct for your machine, filament and toolhead by performing and ESTEPS calibration

For proper operation, the ESTEPS for every toolhead need to be and stored in the printer.

Change and save ESTEPS of 415 using the instructions in this handy video Video: How to store ETEPS in a LulzBot TAZ 3D printer (the Cura steps apply to the Mini as well)

(Optional) Calibrate ESTEPS:

For best operation, it's a good idea to calibrate the ESTEPS to minimize under or over-extrusion

To calibrate ESTEPS:

- Open Cura

- Load a model (it doesn’t matter what)

- Open the Control window

- Heat up the nozzle to the proper printing temperature for your filament

- Load your filament using the extrude 10mm button- around 50mm should do it.

- Mark the filament at 100mm and 120mm above the idler

- In the lower right of the control window, there is a white text box where you type in the appropriate Gx Fxx Exxx (USE CAPITAL LETTERS) below, then press enter

- G92 E0

- For Flexible filament: G1 F30 E100

- For Solid filament: G1 F50 E100

Fxx is the feed rate in mm, Exx is the length of filament to extrude. It’s also good idea to calibrate your other toolheads, if you’ve not done so.

- The toolhead will extrude, then stop.

- Make note of how high or low above the toolhead the 100mm mark fell. If it over-extrudes past the 100mm mark, you can measure to the 120mm mark to gauge how much it over-extruded

- Adjust the ESTEPS, increase or decrease them approx. 6 steps per 1 mm of under or over-extrusion, then save them to the printer:

- M92 Exxx

(this sets the new ESTEPS. E400, E432, E411, etc) - M500

(this saves the ESTEPS to the printer) - M501

(this displays the settings, check that your new ESTEPS are saved)

- Close the control window

- Repeat from step 3 until the 100mm mark reaches the point you measured from (the toolhead is extruding 100mm)

Repeat this process for flexible filament you use. We have found that ESTEPs may vary depending on the flexibility of the filament used, so it’s a good idea to calibrate ESTEPs for your filament.

Here's a good summary of the process found at lincomatic.com to fine tune your thermistor PID settings in your printer's Marlin firmware to better maintain hot end temperature:

- Allow your hot end to cool to room temp.

- In the terminal in Cura, send the following command: M303 S230 if extruding filament at 230. Change the number in the command to reflect the temperature at which you normally extrude. The M303 SXXX command will tune the extruder.

The hot end will then heat up and finally cool, while logging the temperature. When completed, similar values will be displayed:bias: 101 d: 101 min: 145.48 max: 154.02

Ku: 64.06 Tu: 29.67

Clasic PID

Kp: 19.5

Ki: 1.5

Kd: 63.48

Type that information into the Cura terminal box using the following format, with your values substituted appropriately, then press enter:M301 P19.50 I1.50 D63.48

Enter the following command and press enter to save the PID settings to EEPROM.M500

We've found that correct ESTEPs for the E3D Titan Aero vary depending on the stiffness of the filament. Softer filaments need around 25% higher ESTEPs, and medium flex filaments need around 10% higher.

Here's how to set ESTEPs for different filaments in Cura LulzBot Edition. We know it's a bit of work, but it will make swapping between flex and solid filaments quick and easy!

- Note the ESTEPs on the label on the toolhead- either on the back or on the stepper motor. If you don't have the label handy, start with 400 ESTEPs for solid filaments

- Open Cura LulzBot Edition (direction Below based on Cura LulzBot Edition Version 21.0X)

- "Machine" menu

- "Add New Machine..."

- LulzBot Mini

- LulzBot Mini with Flexystruder

- Finish

- "Machine" menu

- Ensure the Machine you just added is selected

- Machine Settings

- Change Machine Name

- Enter a new name that will be useful like LulzBot Mini Aero Flexibles, Click OK

- In the "E-Steps per 1mm of filament", enter appropriate ESTEPs for the filament you are printing. Around 400 for solid, 440 for semi flexible, 500 for soft filaments. Click OK

- Follow the steps in "calibrating Your Toolhead" to get the correct ESTEPs for your filament and toolhead on your printer

- Repeat from Step 3 for each of the filaments you intend to use. We recommend at least 1 "Machine" for each of solid and flexible filament.

- Machine Menu

- Select the "Machine" you that you intend to use that you created earlier (LulzBot Mini Aero Flexibles)

- Select the filament and quality you want to print

- If printing flexibles, check that a .5mm nozzle is set in the profile

- Expert Menu

- Switch to Full Settings

- Yes to "Copy the settings from quickprint...."

- Advanced tab

- Check that Nozzle size (mm) is .5mm

- We DO offer additional optional E3D nozzles in different sizes!

- You can Save the profile settings to preserve the nozzle size and any other tuning you've done

- File menu> Save Profile, Save the .ini file somewhere convenient.

- File menu> Open Profile to load the .ini file you created later

- Video: How to load filament with the E3D Titan Aero

- Heat the hotend to a suitable filament change temperature- 200C is good for ABS, PLA, PETG, TPU

- Trim the end of the filament square

- Ensure the tension knob is set properly- approx 2 turns from fully loose for solid filaments. Some flexibles need another 1-2 turns tighter.

- Push the filament in through the hole in the filament lever until it is pressing with moderate pressure against the hobbed bolt below the filament lever

- In Cura, extrude approx 100mm of filament until the new filament pushes the prior filament out through the nozzle. This is known as "purging" the old filament.

- Push the filament down into the idler until the hob has grabbed the filament and is feeding the filament.

- Be sure to not leave PLA sitting stationary in a heated hotend, or to heat it past recommended temperatures, as this can cause crystallization, possibly requiring replacement parts.

- We do not recommend manually inserting or removing filament, as improper removal can result in jamming

- We have found that a good starting tension knob adjustment is 1.5 turns for hard filament and 2-3 turns for softer filaments.

- Per the E3D Titan Aero Wiki's "Adjusting Idler Force" section: "The idler force can be adjusted using the thumb wheel on the side of the extruder. The nut and spring that actually apply the force can be viewed through the lid, giving a quick indicator of the force being applied. The force required will depend on a range of parameters, such as filament material, filament diameter, extrusion rate etc. As a general rule softer filaments (such as flexibles) will need less force than harder ones as the hobb can more easily grip them. The idler force does not need to be perfect in order to print, however to get the best settings for your printer and material combination we advise a little bit of experimentation to find a setting that feels right."

- Change the filament diameter in your Cura profiles to 1.75

- Reduce retraction distance by half or more to avoid retracting the filament up into the heat break or filament guide. Do this in the Start .Gcode section- change the line G1 E-30 F100 to G1 E-15 F100

- Save the filament profile for later use

To swap out a nozzle, you must follow this procedure - being careful not to burn yourself.

Here's a video on How To Remove and E3D Nozzle

- Unscrew the heat-break from the HeatSink half a turn to be sure you are not tightening against the heat-break in later stages.

- Heat up your HotEnd to 285°C. Do not overshoot as you risk damaging your thermistor.

- Remove the existing nozzle from the heater block.

- Insert the new nozzle.

- Gripping the heater block tighten the nozzle. Do not apply any torque through the heat-break, they are fragile.

- Turn off the heat and allow the HotSide to cool.

- Re-tighten the heat-break into the HeatSink.

Heat the hotend to printing temperature for the loaded filament

Loosen the idler tension knob all the way by turning clockwise until it stops

Pull the idler toward you so it's no longer pressing the filament against the hob gear

Try pushing the filament through manually.

If you can get push the filament through through, check the hob for plastic debris and clean as necessary (be sure to rotate it to see all the ridges)

Tighten the idler tension bolt again around 1.5 turn CCW

From the LCD or Cura, extrude around 40mm of filament to purge the filament

To remove the filamant after purging: From the LCD or Cura, retract around 40mm of filament, pulling up on the filament with moderate force to ensure the filament is fully removed from the idler which prevents blobs of filament hardeneing between the idler bottom and hob gear, preventing removal in the future.

If these steps fail, there may be a filament frangment stuck in the filament path. Try disassembling the toolhead to clear the filament path.

Here's a video on How To Disassemble the IT-Works Titan Aero Toolhead

- Open Cura

- Load a file to print (it doesn't matter which)

For additional great information, visit E3D’s Titan Aero Wiki

therealfugu (verified owner) –

Wasn’t sure if this would be worth the price. Totally was. Plug and play (with a little calibration), everything lined up perfectly.