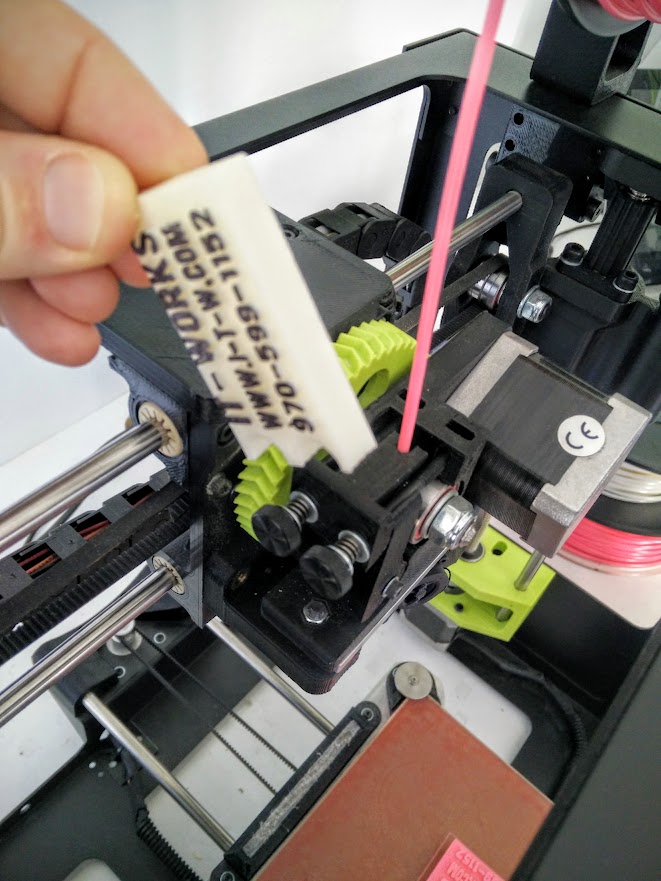

Tool to set idler tension on Lulzbot 3D printers

For consistent filament extrusion with a LulzBot 3D printer, be sure to check that the idler springs have proper tension. Lulzbot…

Featuring Lulzbot 3D Printers, Parts, Toolheads, Filament, and Supplies

For consistent filament extrusion with a LulzBot 3D printer, be sure to check that the idler springs have proper tension. Lulzbot…

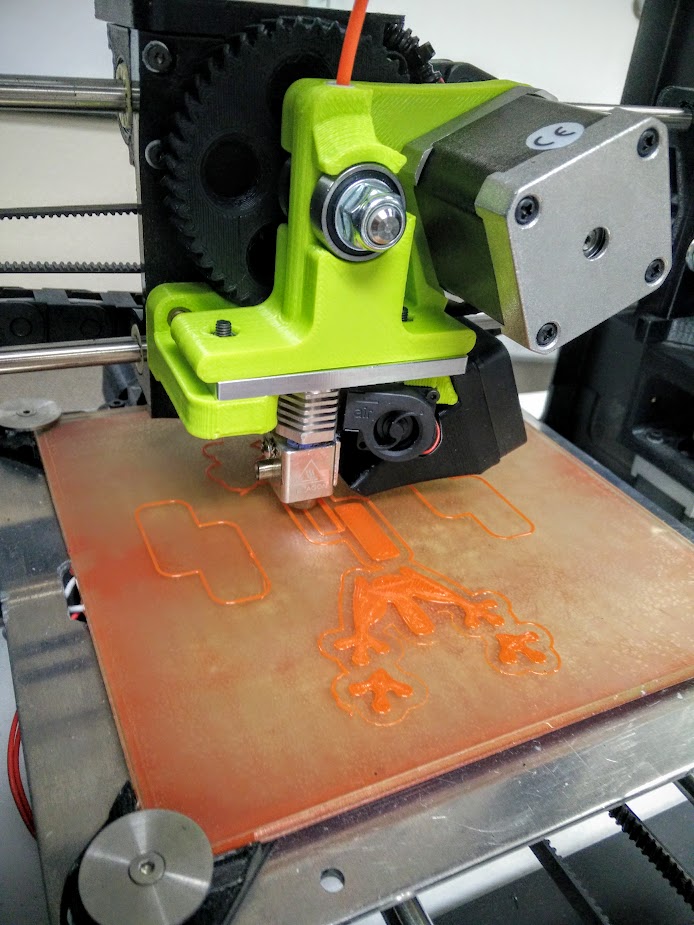

Lulzbot recently released the “Flexystruder V2” toolhead for their Mini 3D printer that enables printing of flexible filaments like Ninjaflex…

How does Eva Hakansson, builder and rider of the world’s fastest electric motorcycle the KillaJoule make holiday treats? With her Lulzbot TAZ…

Work continues on the build of a pink Lulzbot Mini 3D printer. Nearly all the parts are printed, and the…