Description

PRINT IN ABRASIVE MATERIALS WITH SPEED AND STRENGTH!!!

IT-Works developed this toolhead for the LulzBot® TAZ around the E3D Titan Aero extruder and Volcano hot end to give you the ability to print high speed strong prints. It does this by using a 1.2mm nozzle, which allows thicker layer heights of .3mm-.8mm or more, printing upwards of 80-100grams per hour. The thicker layer width requires fewer passes to achieve thick shells, and the larger filament extrusion makes for stronger prints with better adhesion between layers.

Benefits include:

- Printing Abrasive materials, high strength materials would normally cause wear and tear on normal toolhead equipment

- Built in LED for easy layer viewing and a High Visibility 360 degree cooling duct

- Precision machined gears ensure accurate ESTEP calibration, and make for more consistent performance over time

- Surround cooling duct improves print performance. Here’s a real world example E3D Titan Aero duct improves print performance

- Titan Aero is built on the E3D V6 all metal design, allowing you to reliably print any thermoplastic at temperatures of more than 300°C.

- It’s also been designed to take standard V6 heatbreaks, so that you can interchange components from E3D’s entire modular ecosystem to suit your needs.

- 40W heater included for fast heat times, and full melting capabilities

- Available for 1.75mm filament, giving you a wider filament selection. Consider going this route. Cura 3.XX makes it easy to set up a machine and profiles for 1.75mm

The included nozzle size is 1.2mm

Includes a Heardened Hobb Gear, Hardened E3D Nozzle, and either a Titanium Heat break or a Micro Swiss Wear Resistand Heat tube, depending on the filament size.

– 24V power supplies (all TAZ 3,4,5,6)

– Flash printer to LulzBot®’s MOARSTRUDER Hexagon Firmware for TAZ 5 and TAZ 6 with firmware update with Cura LulzBot® Edition)

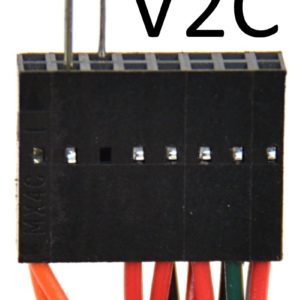

– V2C toolhead connector

60 day warranty and support from IT-Works

*** This is not a LulzBot® product and LulzBot® does not support or warranty this toolhead ***

For best results with your toolhead, please follow the guides below

Q&A:

How to order with upgraded parts

Add all the items you want with your toolhead to the cart(Hardened Hobb Gear, Hardened Nozzle, Either a Titanium Heat Break for 1.75 and Wear Resistant Heat Break for 3mm, all necessary parts for printing abrasive material).

We keep the original parts and install your parts. Simple as that, with no extra labor cost involved.

Please allow up to 2 days for your toolhead to be built and tested.

Q: Can I just turn the feed rate up on the LCD 10% for semi-flexible and 25% for flexible filaments?

A: We suggest starting with higher base ESTEPs first. You can use the feed rate knob to fine tune extrusion.

Q: If I have a 3mm Titan Aero, can I print 1.75mm filament?

A: You can, but with a few qualifications.

- Ideally (but not required) you swap the E3D 3mm filament guide for a 1.75mm filament guide https://itworks3d.com/product/e3d-filament-guide-titan-titan-aero/

- Don't print 1.75mm flexible filaments in a 3mm Titan Aero. The heatbreak and hotend would still be 3mm, making room for flexible 1.75 to coil and bunch up

- You'll need to experiment with flow and retraction retraction settings.

Q: Can I print faster with the Titan Aero toolhead without losing quality?

A: Testing has shown very good results with 50-100% faster print speeds, Try it!

Q: Where are the files for the printed parts?

A: Here you go! https://www.thingiverse.com/ITWorks/designs

Q: How about versions for the LulzBot Mini and dual/multiple filaments?

A: Here's the: E3D Titan Aero Toolhead for LulzBot Mini, we don't plan to offer a Mini Volcano though.

We now offer the Palette+ 4 filament system. Check it out for use with your Mini or Taz 4/5 or 6. Only for 1.75 filament.

Q: What parts do I need to build my own E3D Titan Aero toolhead for the LulzBot TAZ?

1 E3D TITAN AERO EXTRUDER 24V Mirrored

1 .5mm E3D V6 nozzle (a .4mm nozzle is included with the Titan Aero Extruder, if that works for you)

1 2x8 dual row connector housing

15 CONN PIN 24-30AWG CRIMP TIN Type Molex 0016020108 Male. Buy extras though if you're new to crimping these. We've found a PAD-11 crimper to be a good choice to crimp them.

1 FAN BLOWER 51.3X15MM BALL BEARING 24V RADIAL

1 FAN 40X10MM 5V AXIAL

1 MICRO SWITCH

1 FULL HEIGHT NEMA 17 STEPPER MOTOR. You CAN use half height stepper motors (and potentially even pancake steppers), but we've found them to not have enough torque in some situations.

1 screw kit

2 CONN QC RCPT 22-26AWG 0.110 (24-26awg insulated spade lugs. We use TE Connectivity 7-520366-2

1 CONN RING CIRC 22-26AWG #4 CRIMP We use Panduit P22-4R-M

Add all the items you want with your toolhead to the cart(Hardened Hobb Gear, Hardened Nozzle, Either a Titanium Heat Break for 1.75 and Wear Resistant Heat Break for 3mm, all necessary parts for printing abrasive material).

We keep the original parts and install your parts. Simple as that, with no extra labor cost involved.

Please allow up to 2 days for your toolhead to be built and tested.

A: We suggest starting with higher base ESTEPs first. You can use the feed rate knob to fine tune extrusion.

A: You can, but with a few qualifications.

- Ideally (but not required) you swap the E3D 3mm filament guide for a 1.75mm filament guide https://itworks3d.com/product/e3d-filament-guide-titan-titan-aero/

- Don't print 1.75mm flexible filaments in a 3mm Titan Aero. The heatbreak and hotend would still be 3mm, making room for flexible 1.75 to coil and bunch up

- You'll need to experiment with flow and retraction retraction settings.

A: Testing has shown very good results with 50-100% faster print speeds, Try it!

A: Here you go! https://www.thingiverse.com/ITWorks/designs

A: Here's the: E3D Titan Aero Toolhead for LulzBot Mini, we don't plan to offer a Mini Volcano though.

We now offer the Palette+ 4 filament system. Check it out for use with your Mini or Taz 4/5 or 6. Only for 1.75 filament.

1 E3D TITAN AERO EXTRUDER 24V Mirrored

1 .5mm E3D V6 nozzle (a .4mm nozzle is included with the Titan Aero Extruder, if that works for you)

1 2x8 dual row connector housing

15 CONN PIN 24-30AWG CRIMP TIN Type Molex 0016020108 Male. Buy extras though if you're new to crimping these. We've found a PAD-11 crimper to be a good choice to crimp them.

1 FAN BLOWER 51.3X15MM BALL BEARING 24V RADIAL

1 FAN 40X10MM 5V AXIAL

1 MICRO SWITCH

1 FULL HEIGHT NEMA 17 STEPPER MOTOR. You CAN use half height stepper motors (and potentially even pancake steppers), but we've found them to not have enough torque in some situations.

1 screw kit

2 CONN QC RCPT 22-26AWG 0.110 (24-26awg insulated spade lugs. We use TE Connectivity 7-520366-2

1 CONN RING CIRC 22-26AWG #4 CRIMP We use Panduit P22-4R-M

Installing, Using, and Maintaining the LulzBot® TAZ E3D Titan Aero toolhead:

For additional great information, visit E3D’s Titan Aero Wiki

eobrien –

Got this toolhead around 6 months or so and just had to come back to relay how much of great addition to my printing arsenal this has been. I use a .8mm nozzle and have been using this create functional pieces while cutting my print times in half and increasing the strength dramatically. Couldn’t be happier!

haha (verified owner) –

I’ve only used this toolhead for a few weeks, but with all the plastic I’ve pushed through it, it seems like it’s been years! Tons of high quality prints have come of the print bed since this toolhead acquisition. I have the 1.2mm Nozzle X (professionally installed by the It-Works 3D team) and it performs like a gem. This thing is so reliable, so well-supported and is dead easy to install on the Taz 6. It honestly performs better than the stock/OEM MOARstruder, and has a wider array of nozzle sizes and options to choose from. Thanks to Zach and the rest of the IW3D team for creating a killer product at a reasonable price point!