Enclosure for your LulzBot Mini

Have your 3d prints split or warped due to a cold draft, or you’d like to have your LulzBot Mini…

Featuring Lulzbot 3D Printers, Parts, Toolheads, Filament, and Supplies

Have your 3d prints split or warped due to a cold draft, or you’d like to have your LulzBot Mini…

IT-Works is proud to stock the full range of Micro Swiss high quality, wear resistant nozzles for LulzBot TAZ and Mini…

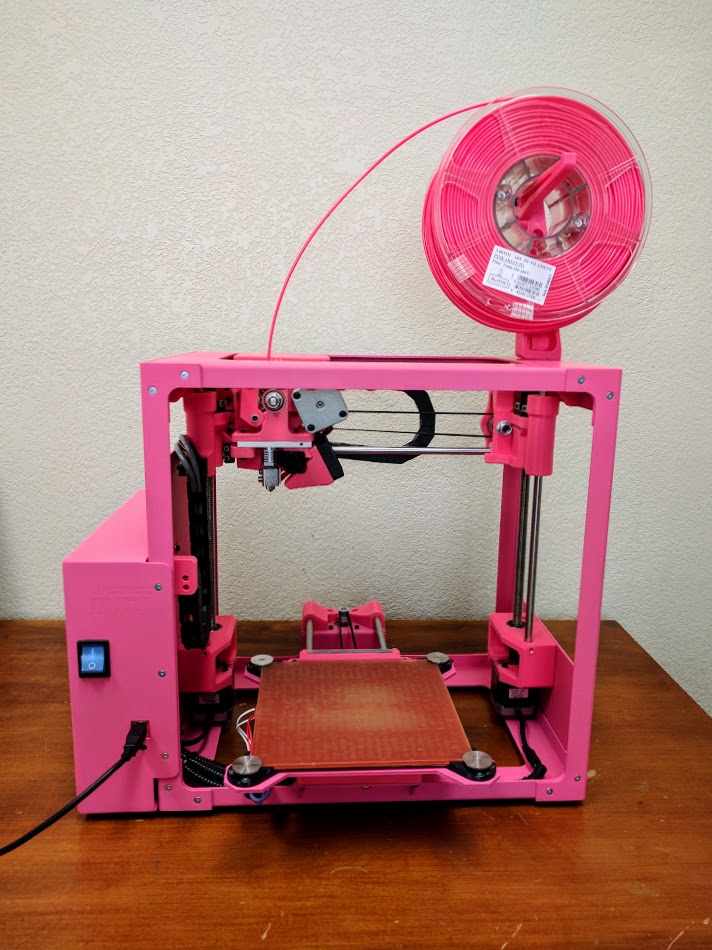

Jodi wanted a pink LulzBot Mini 3D printer for (last 😉 ) Christmas. Jamie and Jodi finally finished it! We…

LulzBot released several updates to the LulzBot Mini firmware that are included with the recent Cura LulzBot Edition version 20….